We respond to customer needs through our integrated production system,

combining core technologies refined from our company's beginnings.

| Category | Example | Features | Specifications / Shape | |

|---|---|---|---|---|

|

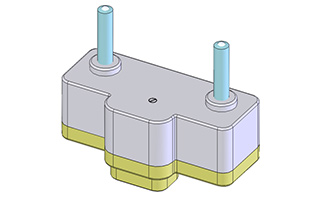

Sensor switch unit |

Side mirror sensor |

Incorporates two sliding position sensors to detect the angle of side mirrors. |

Customized products |

|

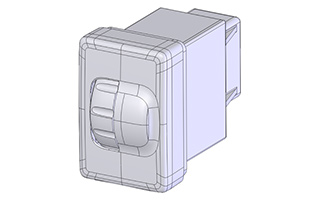

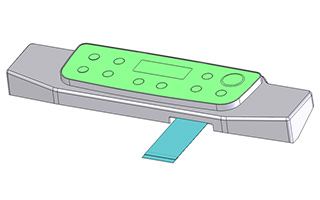

Control switch unit |

Light leveling switch |

Developed using an integrated circuit board with printed resistors. Use of two-material molding technology enables the knob digits to be illuminated if required. Designed to facilitate smooth operation. |

Customized products |

|

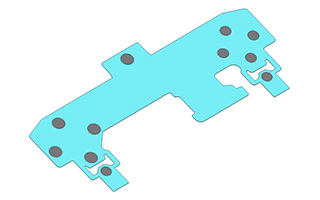

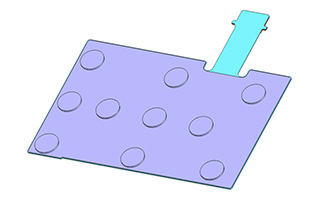

Resistive board |

HVAC actuator |

Printing resistors directly onto rigid circuit boards means we are able to achieve linearity of ±1%. We are able to avoid using gold plating through the use of water-soluble flux. A strip coat finishing is also available upon request. |

Customized products |

|

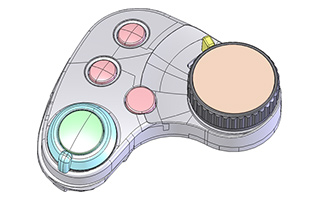

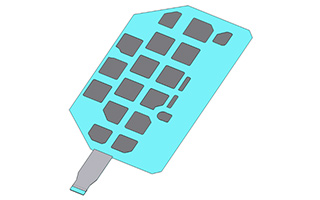

Flexible printed circuit |

Game console controller |

Creating circuits by printing tracks and resistors directly onto PET film enables us to manufacture controllers that are thin and lightweight. |

Customized products |

|

Flexible printed circuit |

Head mounted display |

Printing circuits on PET film enables a thin and lightweight circuit board. This will not negatively affect design and functionality, either. |

Customized products |

|

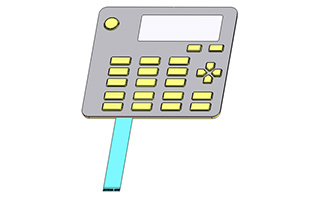

Control switch unit |

Digital camera top operation block |

We make circuits for components such as the release button, mode switch, and zoom lever, etc. by printing onto film, and are able to achieve our client's design requirements. |

Customized products |

|

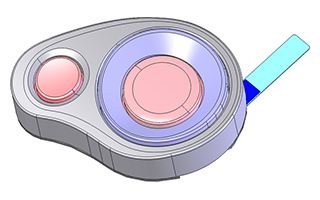

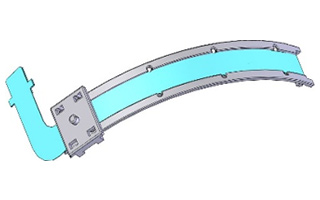

Curve slide sensor |

Rotary sensor for camera lens (body) component |

We are able to place potentiometers on curved surfaces using our unique curved surface resistance position sensor film technology. Our potentiometers can therefore be used as high-resolution position sensors as can sense position directly when cylindrical objects such as camera lenses are in use. |

Customized products |

|

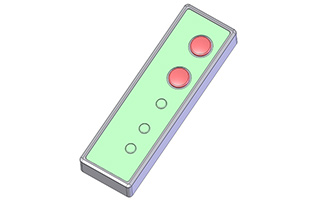

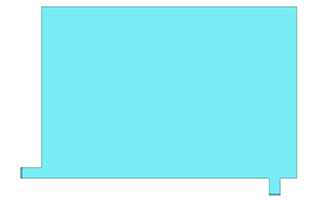

Control switch unit |

Television |

We use decorative technologies such as resin molding and pad printing, as well as assembly technology, to piece the product together and deliver it semi-complete; resulting in less work for our clients. This also helps maintain overall product quality. |

Customized products |

|

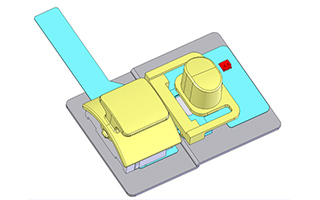

Control switch unit |

Video camera |

Circuits in components such as the start/stop button, zoom, and photo button, etc. are all made using film and created using unique NOBLE technologies. Simultaneous manufacturing of both interior and exterior components enables us to deliver high quality, tactile units. |

Customized products |

|

Control switch unit |

Fan heater |

We use assembly technology to piece the product together and deliver it semi-complete, resulting in less work for our clients. This also helps maintain overall product quality. |

Customized products |

|

Control switch unit |

Refrigerator |

We use 9 mm size of NOBLE potentiometers and deliver products semi-complete, resulting in less work for our clients. |

Customized products |

|

Touch sensor |

Rice cooker |

Use of thin film circuits makes it possible to create capacitive touch sensors. |

Customized products |

|

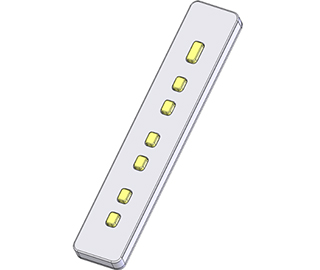

Flexible printed board |

Projector |

LEDs are positioned on film using low-temperature solder mounting technology. Building the switch unit simultaneously allows us to offer our clients compact units that still light up incredibly well. This technology also gives our customers more freedom in product design and makes assembling the product much easier. |

Customized products |

|

Flexible printed board |

Voice recorder |

Printing circuits on PET film means parts will be thin and lightweight. This contributes to a much more compact and lighter product overall. |

Customized products |

|

Flexible printed board |

Electronic blackboard |

We create mutually capacitive static electricity touch sheets by printing silver tracks on both sides of a PET sheet. We are also able to print these to dimensions of 2m x 1.5m using a large-scale printer. |

Customized products |

|

Molded parts |

Blood glucose meter |

We use decorative technologies such as resin molding and pad printing, as well as assembly technology, to piece the product together and deliver it semi-complete; resulting in less work for our clients. This also helps maintain product quality. |

Customized products |

|

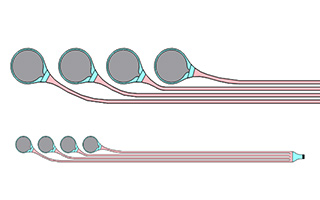

Biological sensor |

Disposable electrodes |

We produce biological sensors by printing on PET film; bringing together a wide variety of printing technologies including multilayer printing, double sided printing, through-hole printing, and foam printing. We are also equipped to meet additional customer requirements such as noise prevention and tactual sense. |

Customized products |

There is no product that corresponds to the specified application.