NOBLE's FPC (Flexible Printed Circuit) is a screen printing technology that has been developed over time and manufactured with the combined flexible characteristics of film.

In forming electronic circuits by "through-hole printing" and "laminated printing" with our screen printing technology, we are able to reduce the overall product size.

By combining the characteristics of film such as "thin", "light", and "soft" with resin molding, it is possible to support various shapes such as curved surface designs as well as thinness and weight reduction.

By mounting parts and assembling products in-house and supplying them as a combined electronic control unit with multiple functions, we are able to reduce the customer's production processes.

We are developing core technologies to meet the increasingly sophisticated and diversified needs of our customers. For example, mass-produced general-purpose resistor substrates that can withstand a life of 10 million cycles with excellent wear resistance. We make full use of through-hole printing and laminated printing to minimize noise interference while providing a cushioned foam feel in our medical / healthcare products. We are also pursuing the development of new products that utilize current design trends, such as touch keys made of transparent conductive ink, touch keys that react even when wet, and non-contact touchless keys that react by hovering.

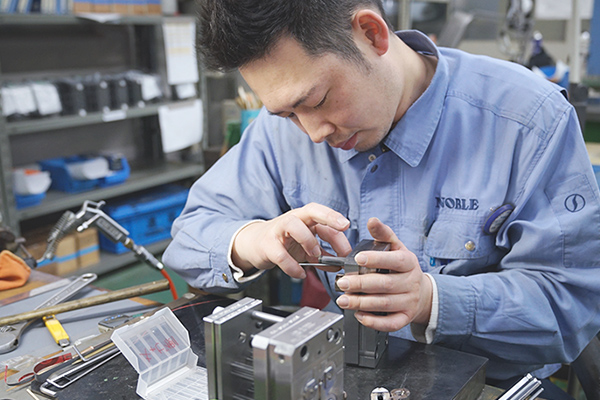

High-precision molds are crucial for manufacturing high-quality parts. Our company group is involved in the design, manufacture and maintenance of molding and press dies. The combined expertise crosses country borders, and our mold manufacturing is also established at overseas production locations.

We handle all aspects from jigs and tools in product manufacturing to the construction of production equipment in-house. Through automation and labor saving, we aim to maintain high quality, improve productivity, and flexibly respond to customers' advanced orders.

Our printing technology by electronic circuit formation is regarded as environmentally friendly because of our screen printing method, which applies ink only where it is needed.

Environmentally friendly manufacturing achieved through our integrated production system. Our entire company group has set up manufacturing that utilizes energy saving, resource saving, raw material saving, and recycling at all stages of development, production, and distribution" as an initiative of the SDGs, and is working toward establishing a carbon-neutral and carbon-free society.